When it comes to tactical gear, personalization and functionality are key. Whether in the military, law enforcement, or an outdoor enthusiast, custom Velcro patches (also known as custom hook and loop patches) offer a convenient way to display identification, rank insignia, or personal flair. However, correctly attaching these patches to your gear ensures they stay secure, especially during high-intensity activities.

In this guide, we’ll walk you through adequately attaching your Velcro patches to tactical gear and maintaining them for longevity. If you’re looking for durable, high-quality custom patches, Custom Patches by Bob offers a wide range of styles perfect for all types of tactical gear.

Understanding Custom Velcro Patches

What Are Custom Velcro Patches?

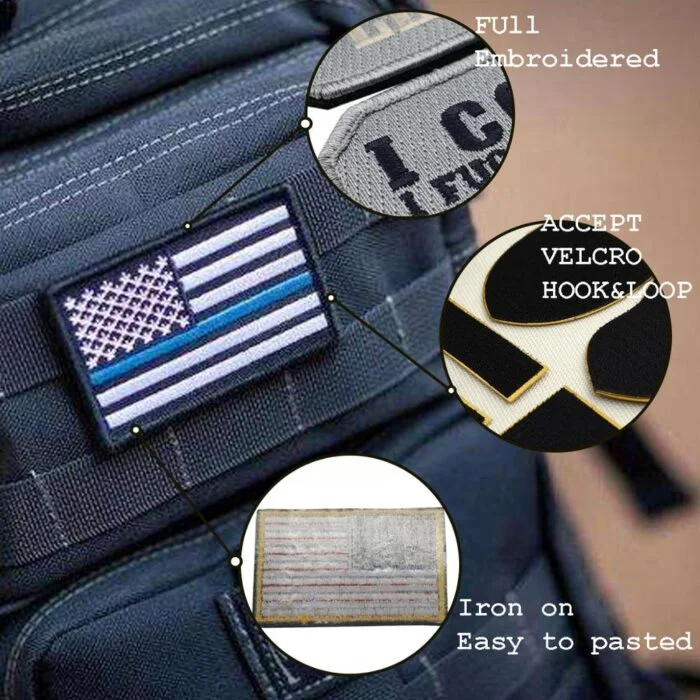

Velcro patches, also known as custom hook-and-loop patches, utilize a two-part fastening system. One side of the patch, known as the hook side, features tiny hooks that can grip onto the loop side, a softer fabric panel usually sewn onto the tactical gear. This system makes attaching and removing patches quick and easy, allowing users to swap patches based on the mission or activity.

Custom Velcro patches come in various styles, including embroidered, PVC, and woven designs. At Custom Patches by Bob, we offer a wide selection of high-quality patches that can be customized with your unique designs, logos, or text. These patches are perfect for tactical vests, hats, bags, and other gear.

Why Use Velcro Patches for Tactical Gear?

There are several reasons why custom Velcro patches are the go-to choice for tactical gear:

- Ease of Use: Velcro patches are simple to apply and remove, making it easy to swap out patches as needed without damaging the gear.

- Durability: When made with high-quality materials, Velcro patches can withstand rough conditions in the field or outdoors.

- Customization: You can customize patches to represent your unit, rank, or personal style, giving you flexibility in how your gear looks.

Preparing Tactical Gear for Velcro Patches

Check for Loop Panels

Before attaching a custom Velcro patch, it is essential to ensure that your tactical gear has the appropriate loop panel (the soft, fuzzy side of the Velcro system). Most tactical vests, backpacks, and hats are equipped with these panels for Velcro patches. If your gear doesn’t have a loop panel, you can easily purchase Velcro loop strips and sew or stick them onto it.

Custom Patches by Bob also provides patches with adhesive backing or sew-on options if you need to attach a loop panel manually.

Cleaning the Surface

The surface of the loop panel needs to be clean and free of debris to ensure a strong bond between the hook and loop patches. Dirt, lint, and other particles can interfere with the hooks on the patch, reducing their ability to grip correctly. To clean the loop panel, use a lint roller or a soft brush to remove any accumulated dirt or fuzz. A clean surface will ensure that your patch attaches securely and stays in place during heavy use.

Attaching the Velcro Patch

Step-by-Step Guide

Once your gear is prepared, follow these steps to securely attach your custom Velcro patch:

- Align the Patch: Hold your patch so the hook side faces the loop panel on your gear. Align it carefully with the intended area to ensure proper placement. Once the patch sticks, it’s harder to realign without losing some adhesion, so it’s essential to position it right the first time.

- Press Firmly: Apply even pressure across the patch to ensure that the hooks fully engage with the loops. Start by pressing in the patch’s center and work toward the edges. Ensure all parts of the patch, especially the edges, are pressed down firmly.

- Double Check for Security: After attaching the patch, gently tug it to test its hold. An adequately attached patch will stay firmly in place without lifting or peeling at the edges.

Proper Placement

Where you attach your custom Velcro patches can affect both their functionality and longevity. Pacing patches in easily visible areas less likely to experience constant rubbing or friction are essential. Typical areas of tactical gear include:

- Chest panels: Ideal for identification and rank patches.

- Shoulders or sleeves: Good for unit insignias or flags.

- Backpacks and hats: Perfect for personalizing non-wearable gear.

Avoid placing patches in high-friction areas, such as under backpack straps, as this can cause the patch to peel or wear down over time.

Tips for Secure Attachment

Reinforcing the Bond

While Velcro patches provide a strong bond, certain situations may require extra reinforcement, especially in high-stress environments. Here are a few tips to ensure your patch stays in place:

- Stitching the Edges: For maximum security, consider stitching the edges of the loop panel onto your gear. This prevents the panel from loosening over time. If you frequently swap out patches, focus on stitching the loop panel rather than the patch to preserve its functionality.

- Velcro Adhesive: If your tactical gear doesn’t have a loop panel, Velcro adhesive strips are a great alternative. Stick the adhesive-backed loop to your gear, and you can attach your patches.

Avoiding Misalignment

Misaligned patches look sloppy and can weaken the connection between the hook and loop sides. Always double-check the positioning of your patch before pressing it down. If you notice any misalignment, peel it off gently and reposition it.

Maintaining Your Velcro Patches and Gear

Proper care is essential to maintaining the strength and longevity of your custom hook and loop patches and the gear they’re attached to. Follow these tips to keep both in top condition:

Regular Cleaning

Dirt and debris can accumulate in the loop panel of your gear, reducing the strength of the Velcro’s grip. Over time, the loops may become clogged, making it difficult for the hooks to latch on properly. To clean your loop panel:

- Use a stiff brush or comb to gently remove dirt and lint.

- A piece of duct tape can also help lift debris out of the loops.

- A quick wipe with a damp cloth should suffice for the patch itself.

Storage When Not in Use

Store your patches attached to a spare loop strip or panel when they aren’t in use. This prevents dust from collecting in the hooks, ensuring they maintain their adhesive quality over time.

Replacing Worn Patches or Panels

Even the best custom Velcro patches will eventually wear out. If the hooks on your patch no longer stick or the loop panel on your gear becomes too worn, it’s time to replace them. Custom Patches by Bob makes it easy to reorder custom patches, ensuring that your gear always looks sharp and professional.

Popular Uses for Custom Velcro Patches by Bob

At Custom Patches by Bob, our Velcro patches are designed for a wide range of applications, including:

- Military & Law Enforcement: Use our patches for identification, rank insignias, unit logos, and morale patches.

- Outdoor Enthusiasts: Personalize your backpacks, jackets, and hats with durable, weather-resistant patches.

- Corporate or Event Branding: Create branded patches for staff uniforms, promotional giveaways, or special events.

With our high-quality craftsmanship and customizable designs, Custom Patches by Bob delivers functional and stylish patches.

Conclusion

Custom Velcro patches are a versatile and practical addition to any tactical gear. Following the steps outlined in this guide ensures that your patches stay securely attached, even in the most demanding situations. Whether in the field or personalizing your outdoor gear, Custom Patches by Bob offers the perfect solution with durable, custom-made Velcro patches that suit your needs.

Ready to enhance your tactical gear with custom patches? Visit Custom Patches by Bob today and start designing your perfect patch!