Custom printed patches have emerged as one of the most popular methods for adding unique, personalized touches to various items, from clothing and accessories to corporate branding and promotional products. Creating custom printed patches involves a combination of creativity, technology, and materials. Among the most effective techniques for making these patches is sublimation, a printing method that produces vivid, detailed designs that stand out and last. In this article, we will explore the process of creating custom printed patches, with a special focus on sublimated patches, and the benefits they offer.

What Are Custom Printed Patches?

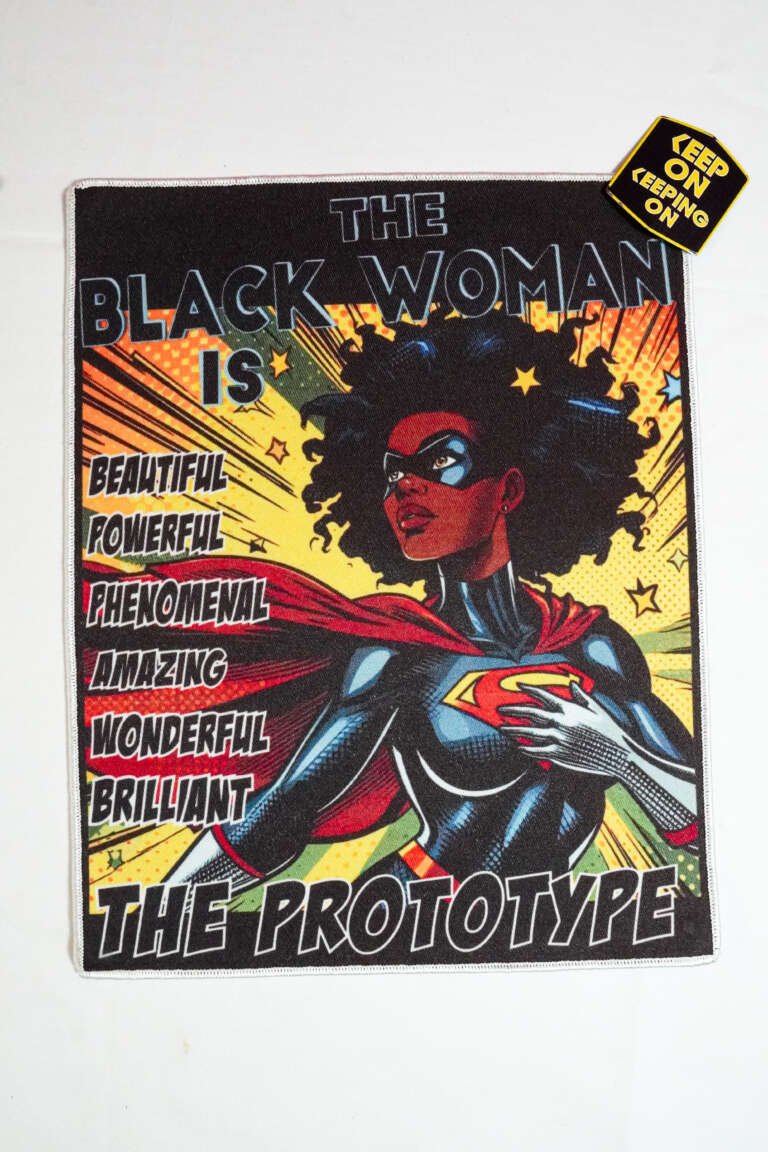

Custom printed patches are vibrant, unique designs transferred onto fabric using printing technologies like sublimation. Unlike embroidered patches, which use stitching, these patches offer intricate details and bright colors. Sublimated patches, a specific type of custom printed patch, use heat and pressure to infuse ink directly into the polyester fabric, creating durable, long-lasting designs with exceptional clarity. These patches are perfect for fashion, personal expression, or branding.

The Sublimation Process

The sublimation process is at the heart of custom printed patch creation, especially when it comes to sublimated patches. Understanding how this process works and why it’s so effective for creating detailed and durable patches is key to making high-quality products.

Step 1: Design Creation

The first step in making a custom printed patch is designing the artwork. Whether it’s a logo, a message, or a unique graphic, the design is created digitally. Designers must carefully choose colors, shapes, and text to ensure the final product is eye-catching and easy to understand.

Step 2: Printing the Design

Once the design is finalized, it’s printed onto sublimation transfer paper using a special sublimation printer and ink. This printer uses dye-based inks specifically formulated for sublimation, ensuring vibrant and precise colors.

Step 3: Heat Transfer

Next, the transfer paper is placed on the polyester fabric or material. The design is transferred onto the fabric by applying heat and pressure using a heat press. The heat causes the dye to turn into a gas, then permeating the fabric fibers, bonding with the material. This results in a patch with vivid, permanent colors that won’t fade or crack over time.

Step 4: Cooling and Finishing

After the transfer process, the patch is allowed to cool. Once cooled, the transfer paper is removed, revealing the custom printed design. At this point, the patch can be cut to the desired shape, and any additional finishing touches, such as adding a backing or border, are completed.

Benefits of Sublimated Patches

The sublimation process offers numerous benefits, making it the preferred method for creating custom printed patches. Here are some key advantages:

- Superior Color Vibrancy and Detail

Sublimated patches are known for their rich, vibrant colors. Because the ink is fused directly into the fabric, the colors remain vivid and do not fade over time. The ability to reproduce fine details and gradients is another key advantage, making sublimation ideal for intricate designs and logos that require precision.

- Durability

Sublimated patches are durable and resistant to fading, peeling, or cracking, even after repeated washes and exposure to harsh conditions. The design becomes part of the fabric, meaning it won’t fray or wear off like traditional embroidered patches.

- No Thread Limitations

Unlike embroidered patches, which are limited by thread colors and textures, sublimated patches can feature an unlimited range of colors and intricate details. Fine lines, gradients, and even photographic images can be accurately reproduced.

- Versatility

Sublimated patches can be made from a variety of materials, but they are most commonly used on polyester fabrics. They can be applied to a wide range of items, including clothing, hats, bags, and accessories, making them ideal for branding, personal expression, or promotional purposes.

Designing Custom Printed Patches

When designing custom printed patches, it’s essential to consider the following factors to ensure that the final product is both visually appealing and effective:

- Color Selection

Choosing the right colors is critical in creating an impactful design. Use complementary colors to ensure that the patch stands out. Bright, bold colors can grab attention, but be mindful of color combinations that may clash or become muddled.

- Simplicity and Clarity

Keep the design clean and simple. While the sublimation process allows for intricate details, overly complex designs may become unclear when scaled down to patch size. Simplicity ensures that the patch is easy to read and visually effective.

- Size and Shape

Consider the dimensions of the patch. A well-proportioned design within the selected size will make the patch visually appealing. Custom shapes, such as circular, square, or unique outlines, can also enhance the overall look of the patch.

- Typography

If the design includes text, ensure that the font is legible. Avoid overly intricate fonts that may become hard to read at smaller sizes. The placement and size of the text should also be considered to ensure that it complements the design.

Choosing the Right Materials for Custom Printed Patches

The material used for sublimated patches plays a crucial role in the patch’s durability and appearance. Common materials include:

- Polyester Fabric

Polyester is the most commonly used material for sublimated patches due to its ability to hold dye and retain color. It’s also soft and flexible and works well with heat transfer techniques.

- Canvas

Canvas is durable and can handle heavy-duty applications. It offers excellent color retention, making it a good option for custom printed patches exposed to frequent use.

- Leather

Leather adds a premium feel to custom patches. While it’s more expensive and may require specialized sewing techniques, it offers durability and a unique look, making it ideal for high-end branding.

Applications of Custom Printed Patches

The versatility of custom printed patches, especially sublimated patches, makes them ideal for a wide range of applications:

- Fashion and Personal Expression

Custom printed patches are often used to personalize clothing, bags, and accessories. They offer a fun and creative way to showcase personal style, hobbies, or interests.

- Branding and Promotional Merchandise

Businesses can use custom printed patches as a branding tool. They are a great way to promote a brand by incorporating logos, slogans, and other brand elements. These patches can be handed out at events, trade shows, or as part of a marketing campaign.

- Sports Teams and Clubs

Sports teams often use sublimated patches for team logos, player names, or event commemorations. These patches can be sewn onto uniforms, jackets, or accessories, adding a professional and cohesive look.

- Commemorating Events or Causes

Custom printed patches often commemorate special events, milestones, or causes. Whether for charity events, military service, or sporting achievements, these patches serve as a symbol of pride and accomplishment.

Custom printed patches, particularly sublimated patches, provide endless creative possibilities. The sublimation process guarantees vibrant, durable, and intricate designs, making these patches ideal for fashion, branding, and personal expression. At Custom Patches By Bob, we help you craft stunning patches by considering key design elements, material choices, and application needs. Whether for business or personal use, sublimated patches are a stylish and effective way to showcase your unique designs.